The growing concerns of mortality, age, illnesses and diseases due to contemporary human activities and growing population have led experts to think over some Hygienic and health practices to ensure safety of the future generations.

These environment related issues are not just growing in India but the world as there is an interdependence between countries as one country’s hazardous behaviour may lead serious impact on other countries in future. This all have shifted everyone’s focus on producing eco-friendly products to ensure safety for all and it is what experts are believing to be the need of near future.

According to Mr Ruby Sehgal, owner of OOM pulp products “The COVID-19 outbreak has disrupted business activities in the Hotel, Restaurant, Café industry. This has affected the demand for eco-friendly disposables. The growing demand for disposable plates during the pandemic has created revenue opportunities for companies involved in bagasse plates manufacturing. Since an increasing number of consumers are growing environmentally conscious, the demand for bagasse plates is anticipated to rise in the upcoming months and years”

Bagasse is waste from sugar mill, which is left after juice has been extracted from the cane. It is typically used as a fuel in the sugar mill or brick kiln, and sometimes as a feedstock agro based paper mills. Paper mill converts it into pulp, which can be moulded into different tableware products.

These naturally manufactured and eco-friendly products will ensure long and safe life for all from dangerous chemicals eg – plastic, and allows families to avoid any aforementioned harmful causes.

How Bagasse plates and bowls are made

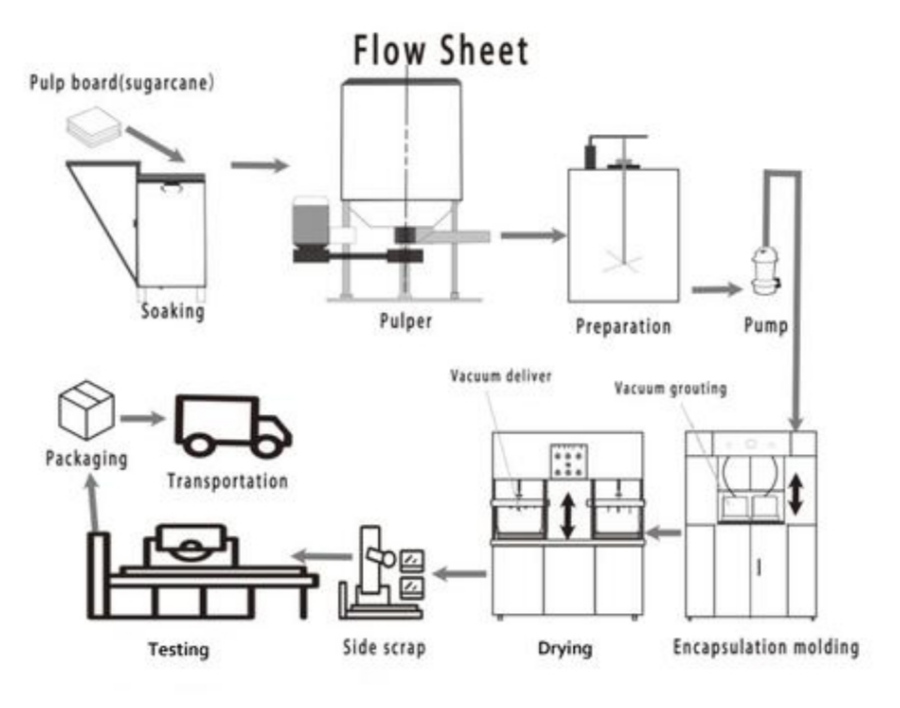

To make the compostable Bagasse plates and bowls, the process starts with the repurposed Bagasse material. The material arrives at the manufacturing facility as wet pulp. The wet pulp is then converted to dry pulp board after being pressed in a beating tank. Bagasse can be made into tableware using either wet pulp or dry pulp board; while wet pulp requires fewer steps in the production process than using dry pulp board, wet pulp retains impurities in its mixture. Transitions2earth takes the extra step to remove the impurities and convert the wet pulp to dry pulp board in order to make higher quality products.

After the wet pulp has been converted to dry pulp board, the substance is mixed with an anti-oil and anti-water agent in a Pulper to make the substance sturdier. Once blended, the mixture is piped into a Preparation Tank and then the moulding machines. The moulding machines instantaneously press the mixture into the shape of a bowl or plate, creating up to six plates and nine bowls at a time.

How effective these products are

The plates and bowls are 100% biodegradable, microwave safe, freezer safe and can completely break down in 90 days in a compost facility. Manufactures takes a waste-product that would end up in a landfill and creates a useful, consumer-ready product with little environmental impact. We are very proud to be one step closer to eliminating waste from landfills. Try our eco friendly range.